Delayed…for the right reasons?

I was looking forward to sharing the shipping deadline in this February update. Unfortunately I need to share that there is a delay. The manufacturer has asked for some time, and to go through another sample round, which means this delay is for the right reasons, and maybe perplexingly I am happy about it… To explain I need to tell a bit of history.

I started to make a stainless steel version in back in 2019 and into 2020 but the manufacturer I was working with at the time went into liquidation part way into the job. At the time this was simultaneously the biggest challenge I had faced running Hone, but also quite the opportunity. It gave me the chance to seek out a new machine shop and hopefully a partner with more capabilities to support me in growing my product line-up and build a more stable and reliable process. I reached out to a well established (70+ years) and very high quality manufacturer in the south of the UK who I had spoken with previously. After some phone calls and online meetings we agreed to work together and started to scope the production of the Type 15s, created timelines, quoted the parts, made agreements and I submitted my PO. Lift-off! Only then would I set-up the pre-order and share the 15s was happening with customers.

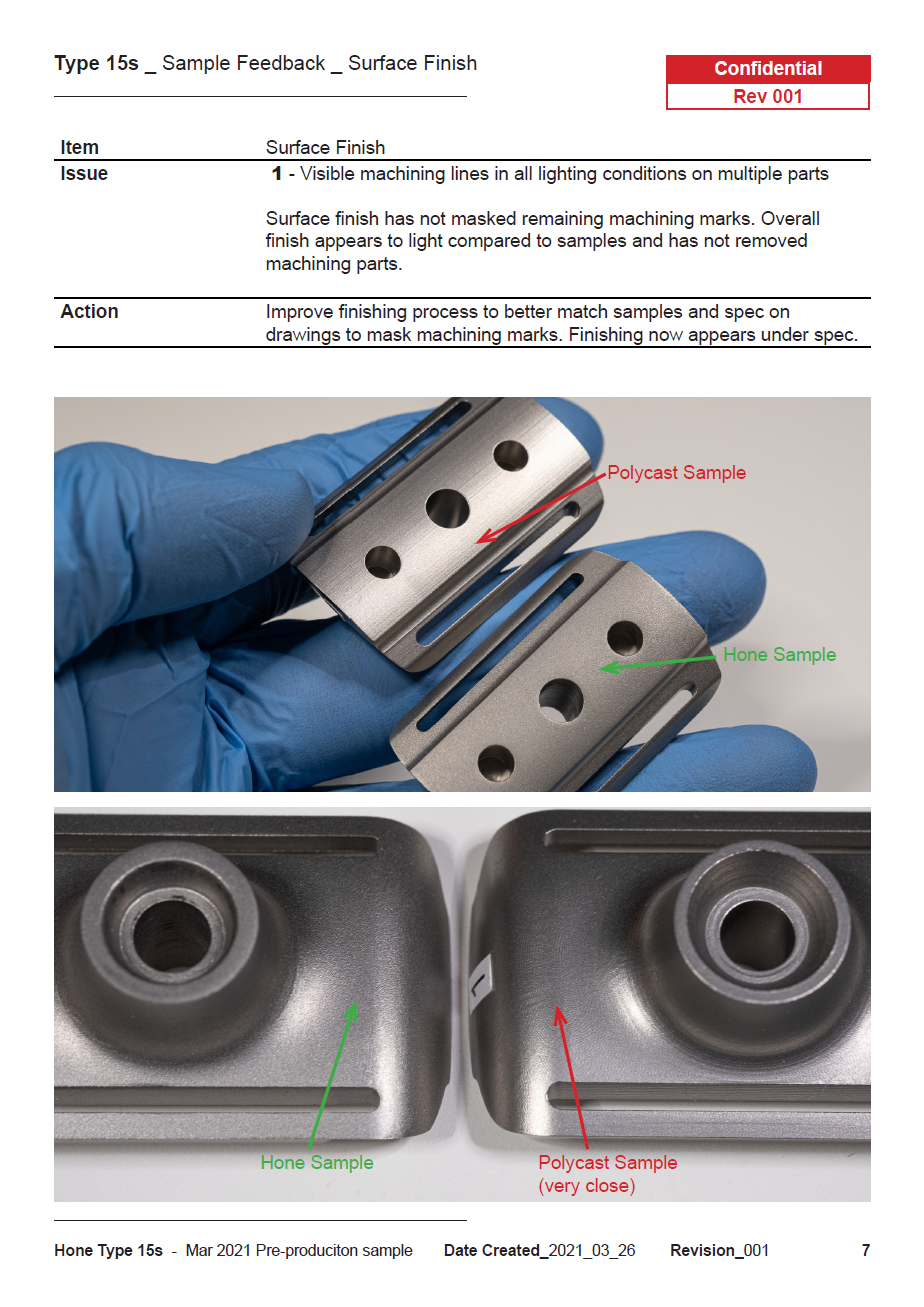

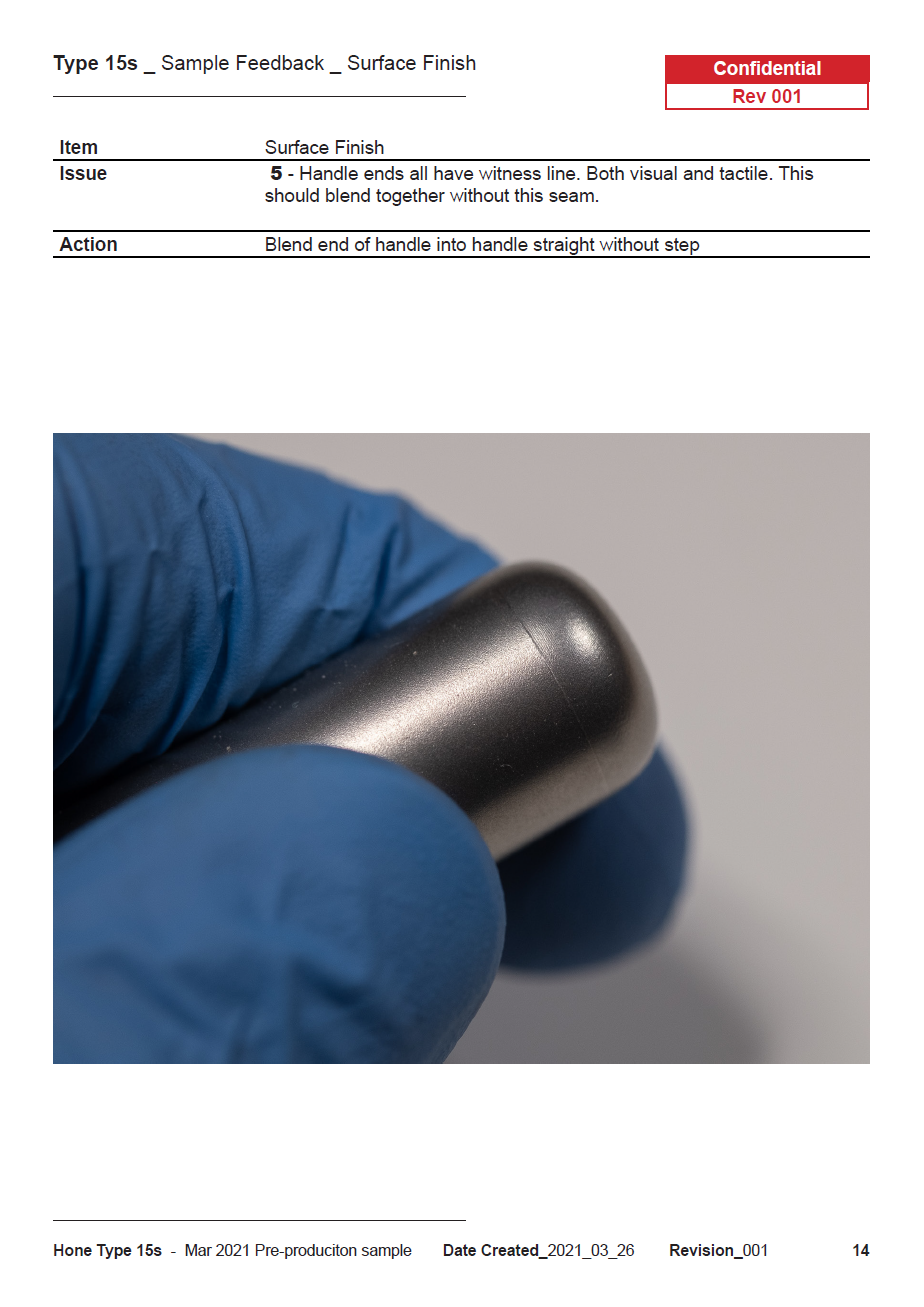

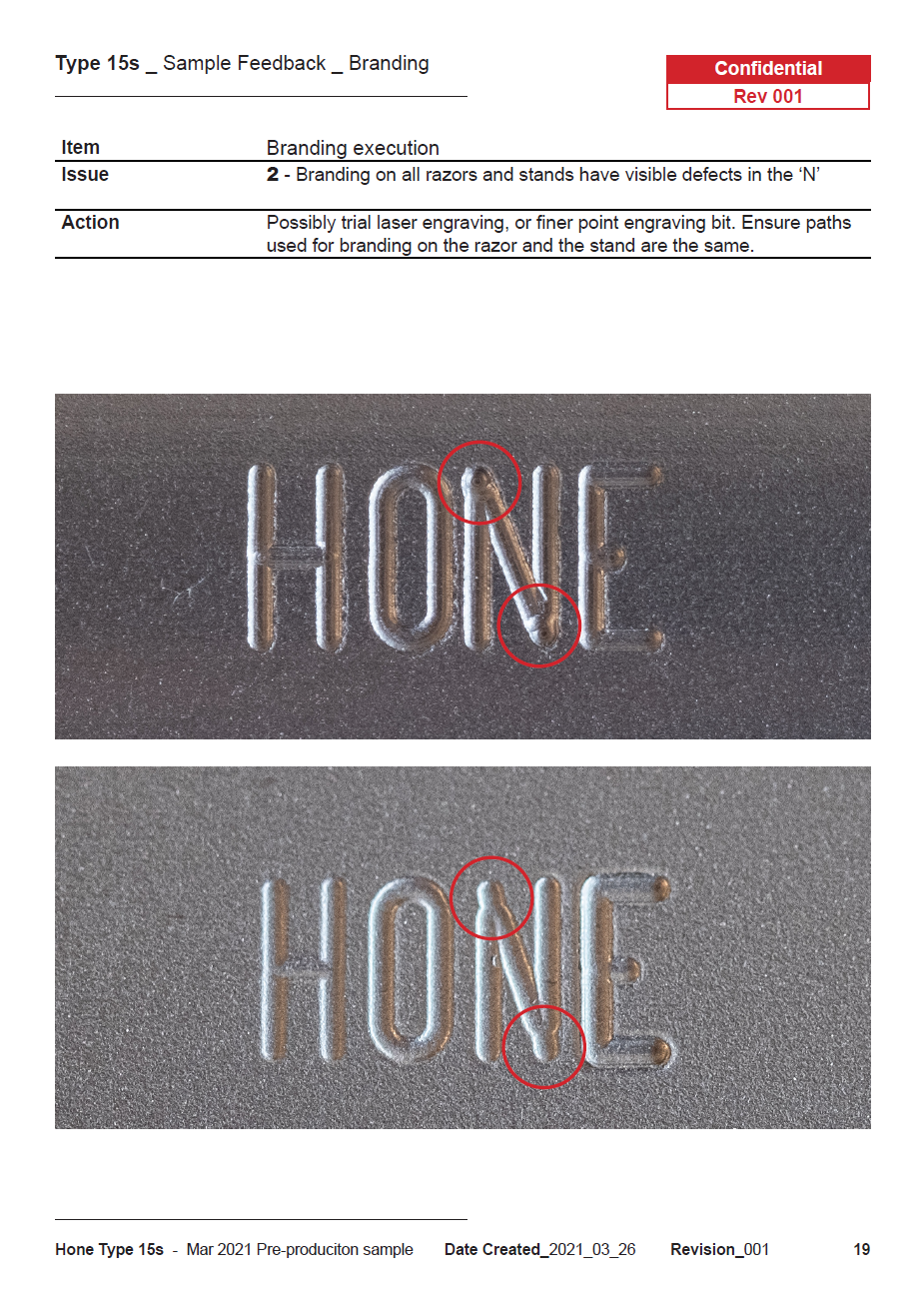

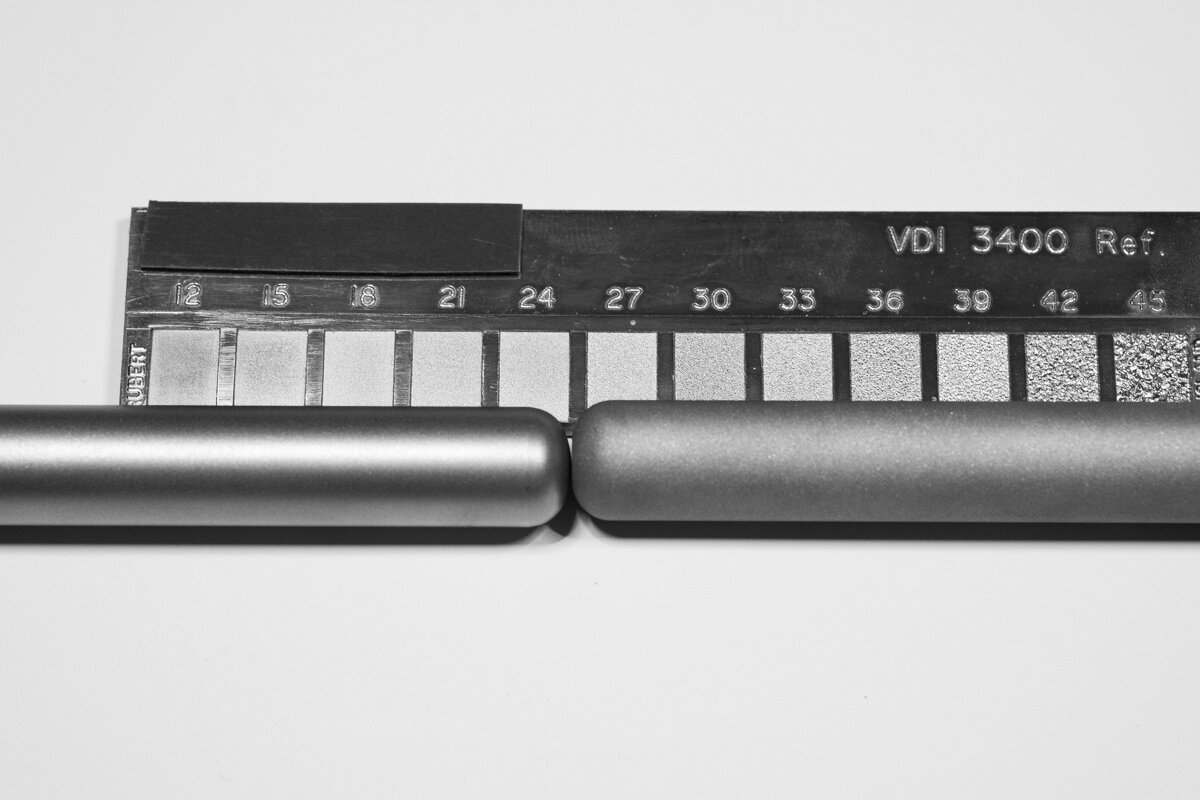

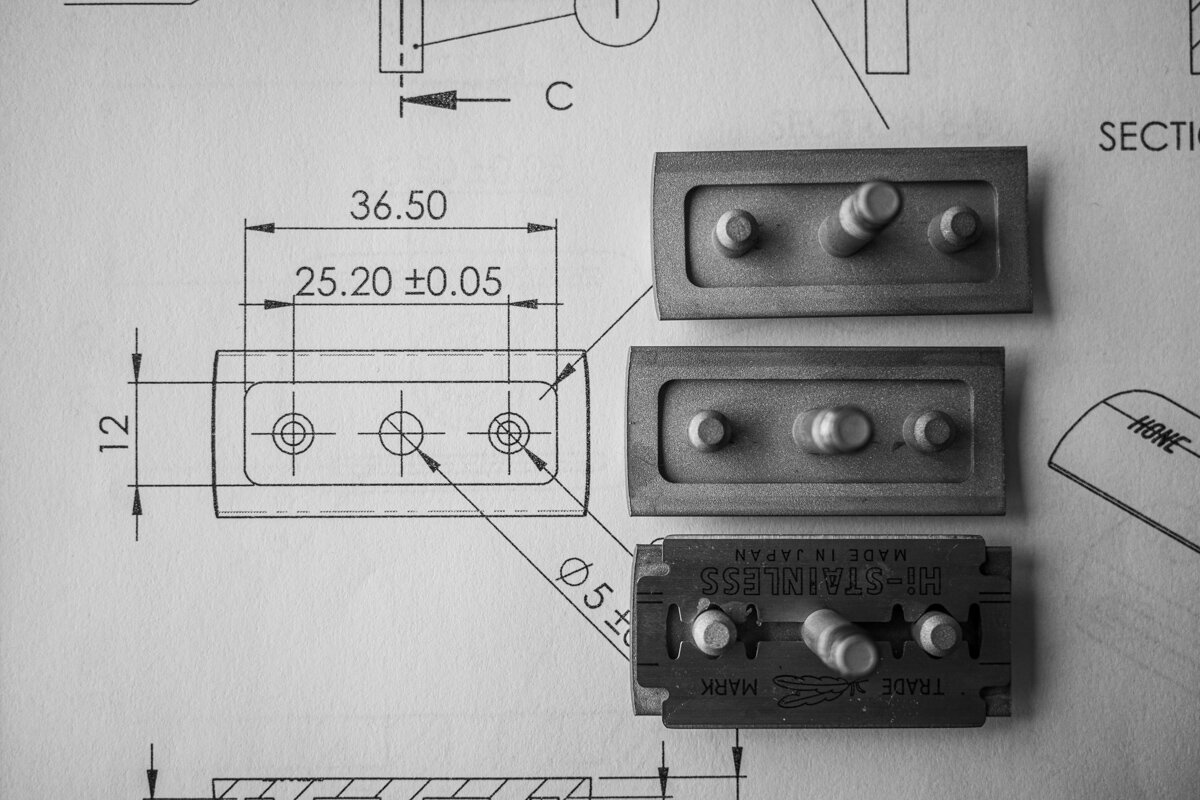

Working with a new manufacturer involves a lot of learning in the first production run. They haven’t made my exact product before so they need to get to know the parts and the best way to handle them. So you go through sample creation to check the tooling, process. Making sure the outcomes match the agreed product and quality spec’s. Well the pre-production samples were spectacular as I shared in my last update; Tolerances, fit, part quality, all top notch. Just a couple of small minor details to iron out with the finishing which we were comfortable were easy tweaks. I was ready to push-the-button on the full batch run... “So what’s the hold up?”

The manufacturer asked for a call in which they requested some space to review the production process on their side. The Type 15 is a deceptively simple design with it’s compound faces and non-planar surfaces that flow together between parts but it can be tricky to make. Even more so in a tough material like stainless steel. And while they had met every spec to the number in the small sample runs, these first attempts had been heavy on time and tooling for them. Having made the parts for real, they asked for some time to find optimisations in the way they run the parts to help deliver them consistently and to maintain that standard. This is something no supplier likes asking their client, especially when they know that I have customers waiting. Doing so requires integrity.

And this explains why I am happy for this delay, this is exactly why I wanted to work with this company. The respectful way they communicated the challenges, and clear communication were exactly the maturity I was looking for. On the one hand I don’t want to have to share a delay with you. But on the other side this delay is for exactly the right reasons; To make sure we deliver the best razors Hone has ever made! I’m not looking for the cheapest place to make my razors. I want somewhere that knows what I am aiming for and shares my values. I am also looking for a partner that helps me do it in a viable and repeatable way and that is exactly why they wanted extra time to develop the process for my parts, so going forward we have a great basis to build upon. And I am confident that this delay will let me reach my goals, and deliver the best razors and shaves possible.

What is the new timeline?

I will be hearing about the timeline of the new sample round this week. As soon as I know I will share. I need that to make the projection for the production.

What else has been happening?

With the delay it means that all the supporting parts are ready to go. In the background all the packaging and materials secured for the shipment of the razors is ready and waiting. So it’s just the main event.